Flagship Q100

Model: Q100-LS02

Key words:

Fully automatic lifting column

Classification:

Product Description

Flagship Q100

Column body cover plate

The cover plate of the column body ensures the compressive resistance of the road pile after it is lowered; the top cover of the column body is turned and the surface is decorated with anti-slip texture.

12V low voltage waterproof LED warning light beads (hidden)

Using DC12V warning light, high brightness, good light transmission; to ensure that the lamp beads can work normally after wading and impact

Imported 3M honeycomb reflective

The reflective film adopts micro prism technology, and the reflective brightness is more than 4 times of the engineering grade and more than 2 times of the traditional high strength grade. The unique reflective principle makes it have a large reflective wide angle at the same time.

Stainless steel column body

The column body stainless steel is processed and formed by a series of processes such as polishing, deburring, rough polishing and fine turning.

Stainless steel panel

The ground panel guarantees the compressive resistance of the road pile after it is lowered; the surface has a non-slip texture decorative design.

Embedded cylinder

The whole is made of carbon steel, and the outer surface of the barrel is painted with high quality metal.

Power Unit

Hydraulic drive, can be immersed in water to work properly, liquid and solid particles of high protection capabilities. High precision sealing, stop dust inhalation.

Seepage(Can be used for drainage)

The bottom of the embedded barrel is provided with a water seepage port to prevent long-term water accumulation, improve work performance and extend service life.

|

Technical parameters |

Functional Parameters |

||

|

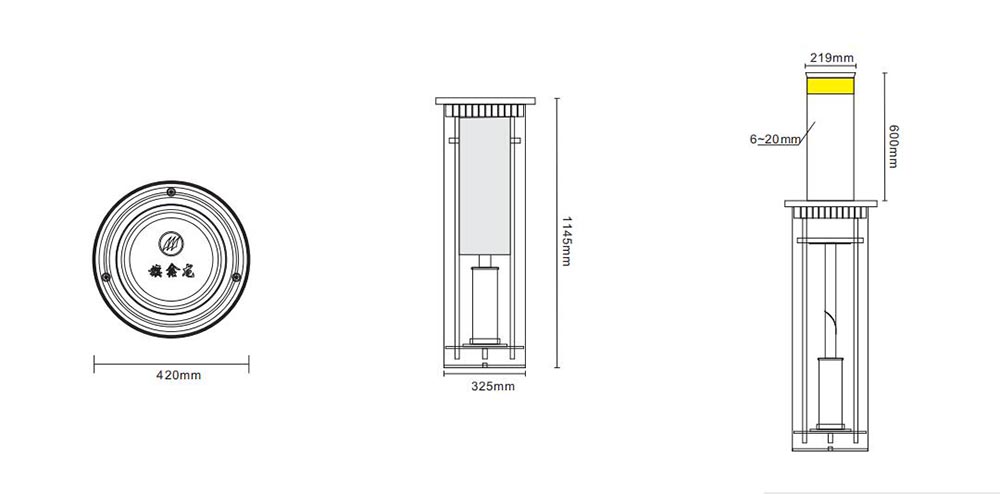

Column lifting height |

600mm |

Anti-collision force |

Normal use after impact with a load of 12 tons |

|

Cylinder diameter |

219mm |

Anti-destructive force |

Deformation of impact road pile with load of 16 tons |

|

Cylinder Material |

High quality non-lure steel |

Assembly structure |

Integrated mounting |

|

Cylinder surface process |

Imported metal car paint |

Drainage mode |

Seepage into drainage system |

|

Cylinder wall thickness |

6 ~ 20mm (customizable) |

Limit mode |

Fixed point in place, NVH (noise, vibration and harshness) |

|

Panel Material |

High quality stainless steel |

Reflective strip |

Imported 3M |

|

Panel size |

420mm diameter |

Warning light |

LED lamp beads |

|

Simplified Material |

High quality stainless steel |

Support protection rod |

Diameter M16 |

|

Cylinder size |

Diameter 325mm, height 1145mm |

buffer heat |

4 |

|

Operation structure |

four-column concentric guide |

Guide protective cover |

4 |

|

Diameter of guide post |

20mm |

Double-layer anti-collision beam |

12mm |

Flagship dedicated movement Model: LS02

Advantages of integrated hydraulic drive

One-piece design, high rigidity structure

The integrated design of hydraulic pumps, hydraulic cylinders, motors, control valves and other components is integrated, which simplifies the installation and enhances the structure with the help of the shell cylinder, which greatly improves the operational reliability.

Ip68 protection class

Benefiting from the innovative structural design, this hydraulic drive can be immersed in water for a long time.

Cache High

In order to meet the needs of a variety of applications, with the help of optimized hydraulic oil circuit, its lifting speed can reach up to 300 mm/s,1.8-2.5 seconds to rise. Cylinder built-in special design of the end of the hydraulic buffer structure, greatly reducing the bottom of the impact of the retraction, and does not affect the lifting speed.

Super corrosion resistance

The hydraulic cylinder shell is made of 304 stainless steel, and the piston rod and cylinder head are treated with QPQ salt bath nitriding (the hardness is 5 times of chrome plating, and the corrosion resistance is 8-10 times). The outer surface of the cylinder is treated with plastic spraying.

Wide temperature adaptability

Built-in heater, and with the heating capacity of the oil immersion motor, can ensure high-speed lifting, normal work at an ambient temperature of minus 40 ℃; and has a built-in motor overheating protection to avoid motor failure to the greatest extent.

IP68 protection class certified by SGS

Model: LS02

|

Technical parameters |

|

|

Height: |

600mm |

|

Power: |

300W |

|

Rated current: |

1-10A |

|

Power |

220V/380V |

|

Connect the power supply: |

3x2.5 |

| Sealing: | Combined seal |

| Rise time: | 3.8-4 seconds |

| Movement structure: | Combined |

| Protection class: | IP68 |

| Power: | 220/380V |

| Maximum force: | 100KG |

| Thermal protection: | automatic induction |

| Descent time: | 1-4 s |

| Driving mode: | Hydraulic drive |

| Service life: | 1 million times |

| Operating noise: | Less than 20 decibels |

| Emergency: | PREPARATION POWER DEPRESSURE |

| Operating temperature: | -20 ℃-75 ℃ |

| Frequency of use: | intermittent use |

Above datais only for reference,Toprevailin kind.

Related Products

online message