Flap barricade

Key words:

Flip barricade series

Classification:

Product Description

flap barricade

1. Safe and reliableIn case of emergency such as power failure, the cylinder can be manually lowered to open the channel and release the vehicle for stable and reliable operation.

2. Affordable Environmental protection and energy saving, low consumption, low failure rate, long service life and low maintenance cost. In addition, the use of non-traditional mechanism design, installation and maintenance, more simple and fast.

3. Unique structureThe hydraulic power unit and the mechanical mechanism are designed as the core part, the mechanical energy can be effectively transferred to the hydraulic drive unit for effective operation.

4. Quickly calm Lifting system time is generally up to 3 seconds, far more than the same specifications of the enterprise pneumatic lifting roadblocks, which is commendable. Because it adopts the development unit driven by hydraulic technology, the action is combined, soft and calm, which solves the problem of the noise of the traditional pneumatic lifting roadblock due to the air pump working environment.

5. Agile Control The control unit uses a common logic controller that can modulate a number of different functional modes to meet the different needs of users with different functions. It is also worth mentioning that the stroke movement is adjustable timing design, the user can freely control the lifting and lowering of the flap, energy saving lifting height.

|

Overall dimensions |

4180*1100*880 |

Oil cylinder power supply |

380V |

|

Blocking width |

4000 |

Cylinder power |

3.0KW |

|

Blocking Gao Liang |

600 |

Cylinder bore |

φ50 |

|

Size of flap panel |

4180*1100*25 |

Cylinder stroke |

230mm |

|

Material of flap panel |

Q235B |

Rising Time |

<2s |

|

Body Material |

Carbon Steel |

Descent time |

2~3s (adjustable) |

|

Spindle diameter |

φ70mm |

Maximum load bearing |

2 to 3 tons |

|

Spindle material |

Q235B |

Solenoid valve voltage |

12V |

|

Quantity of cylinder |

1 |

Waterproof grade |

IP68 |

|

Cylinder |

Double-acting cylinder |

Oil cylinder material |

Steel Pipe |

|

Overall dimension of oil cylinder |

429*390*287 |

flap barricade

Installation method: the hydraulic station is inside the flap barricade and directly connected to 220v power supply. Simple installation.

Hydraulic transmission can output large thrust or large torque, and can achieve low-speed large tonnage movement, which is the outstanding advantage of other transmission methods.

Hydraulic transmission can be very square to achieve a wide range of stepless speed regulation (speed range of 2000:1), speed range, and can be in the process of system operation speed regulation.

Under the same power condition, the wave pressure transmission device is small in size, light in weight and compact in structure. The hydraulic components can be connected by tube or integrated connection. Its layout and installation have great flexibility and can form a complex system that is difficult to form by other transmission modes.

The hydraulic transmission can make the movement of the hydraulic cylinder very uniform and stable, so that there is no reversing impact when the cylinder is reversed. And because of its fast reaction speed, it can achieve frequent commutation.

Simple operation, convenient adjustment and control, easy to realize automation. Especially in combination with machine and electricity, it can facilitate her to realize complex automatic working cycle. Such as the use of electric joint control, not only can achieve a more degree of automatic control process, but also can achieve remote control.

The hydraulic system is easy to realize overload protection, safe and reliable to use. Since the moving parts in the hydraulic components work in the oil and can lubricate themselves, the hydraulic valves and hydraulic pumps have a long service life.

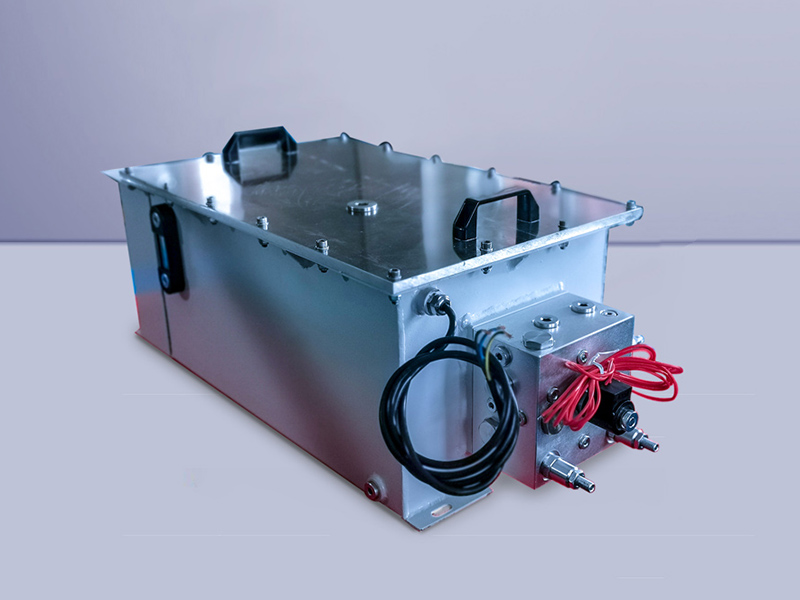

integrated hydraulic system

Double-acting cylinder

Related Products

online message